Joe Austen

Mechanical Design Engineer

44 Center Street

Algonquin, Illinois 60102

Cell Phone: 847.739.6520

JoeAusten@outlook.com

Design Portfolio

Home

Professional Portfolio

Foreman Tool & Mold

Reina Imaging

Loop Belt Industries

Central

Machines Inc.

Suncast Corp.

Brake Parts

Inc.

Krygier Design

Inc.

Fox River Robots

Otto Engineering

SeaquistPerfect

Gray Cat Multimedia

Motorola Inc.

Personal Portfolio

Shelly

Blade

Central Machines Inc.

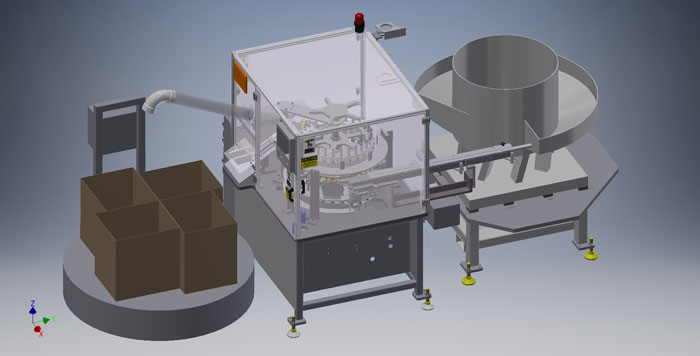

This machine closes flip-top caps which are used on bottles for products such as shampoo, lotion, and ketchup. Flip-top caps are molded in the open position and must be closed so that they can be screwed onto the bottles. The design process utilizes a standard machine configuration that is modified to accommodate the customers flip-top cap.

|

|

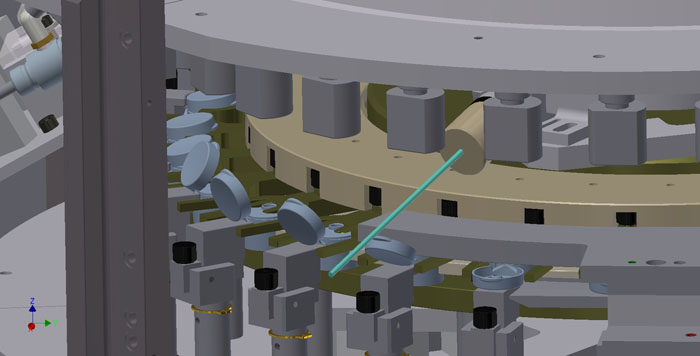

All components and assemblies that contact the flip-top cap are modified.

|

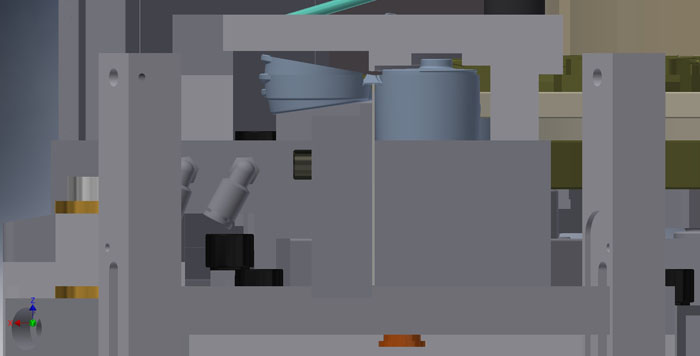

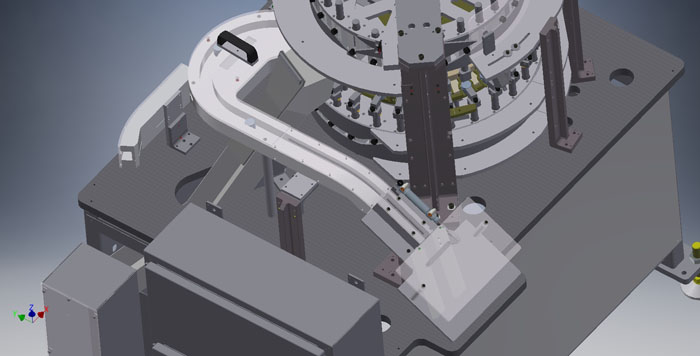

This view shows the air powered transport track that moves the flip-top cap from a vibratory hopper into the closing machine.

|

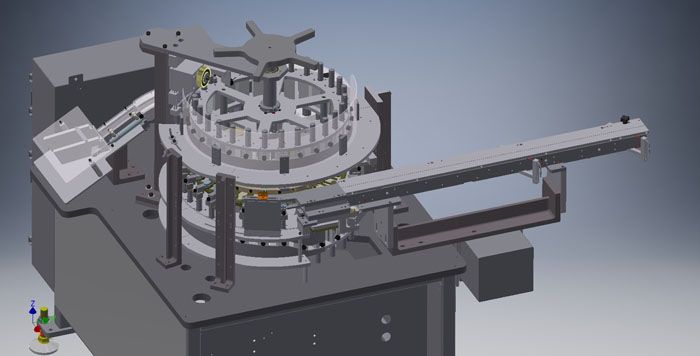

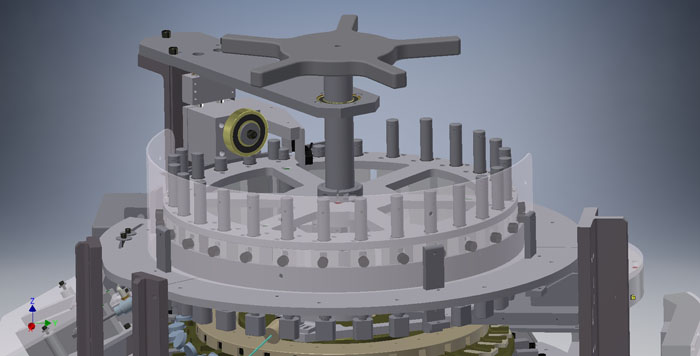

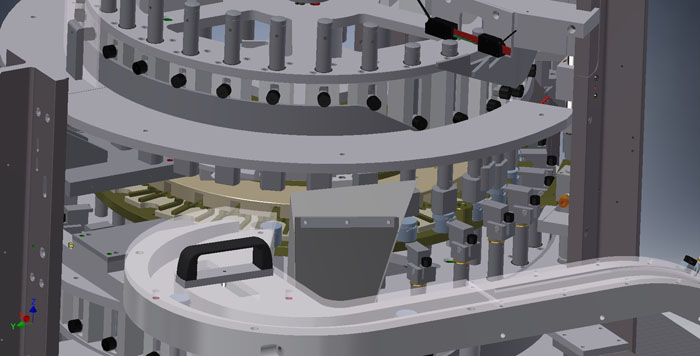

This view shows a rotary dial mechanism. Cam driven upper and lower spindles support and close the flip-top cap. A cam driven fork holds the flip top cap in place.

|

This view shows the mechanism that snaps closed the lid. The upper spindle cam and a hand wheel are shown.

|

This view shows the cap exit track.

|

This view shows the cap exit track with a pneumatically controlled diverted for filling multiple boxes.

|

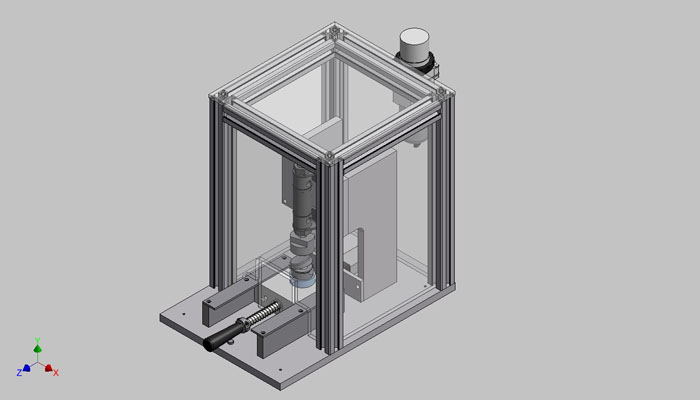

This is a bench top closing machine for flip-top caps.

|