Joe Austen

Mechanical Design Engineer

44 Center Street

Algonquin, Illinois 60102

Cell Phone: 847.739.6520

JoeAusten@outlook.com

Design Portfolio

Home

Professional Portfolio

Foreman Tool & Mold

Reina Imaging

Loop Belt Industries

Central

Machines Inc.

Suncast Corp.

Brake Parts

Inc.

Krygier Design

Inc.

Fox River Robots

Otto Engineering

SeaquistPerfect

Gray Cat Multimedia

Motorola Inc.

Personal Portfolio

Shelly

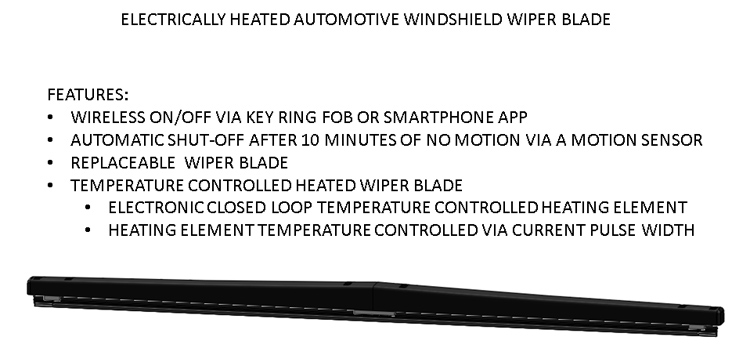

Blade

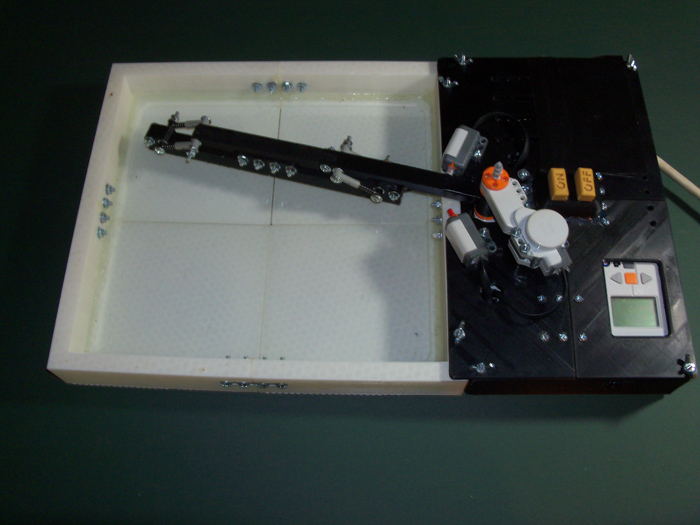

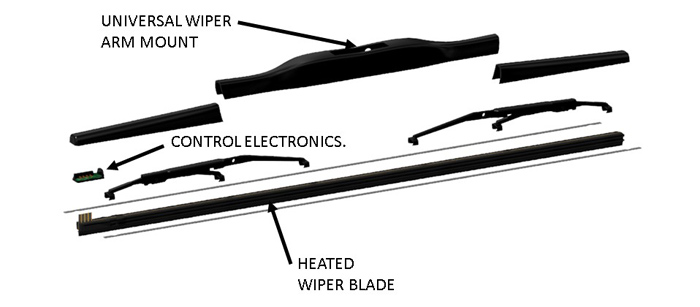

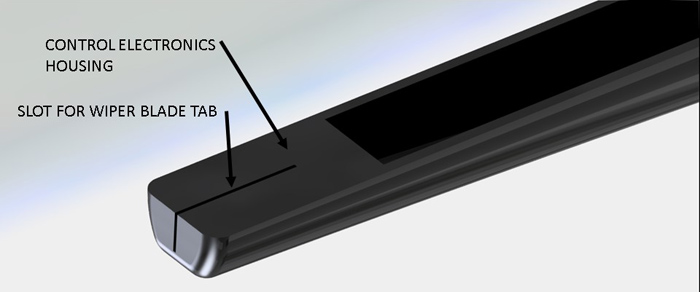

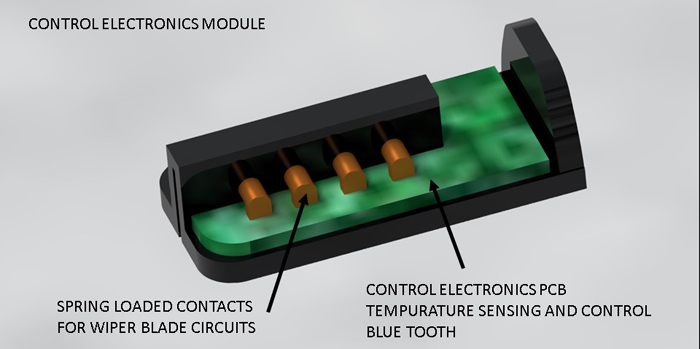

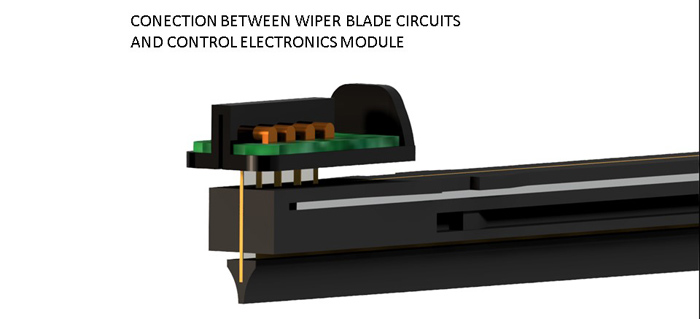

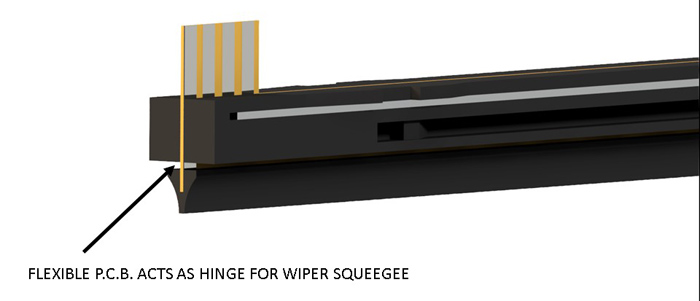

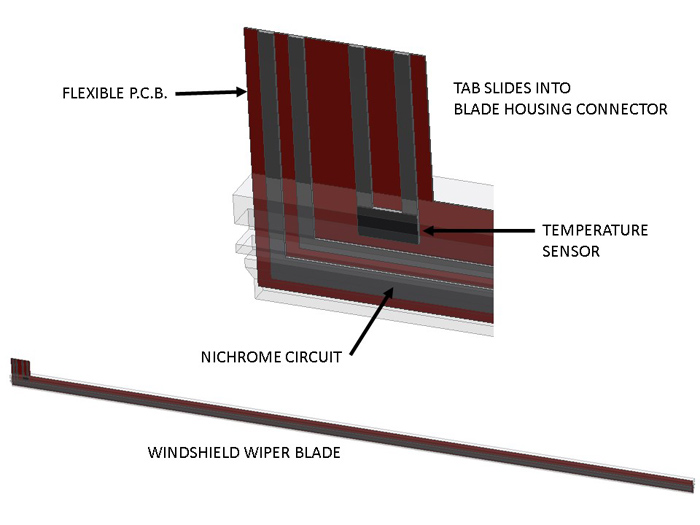

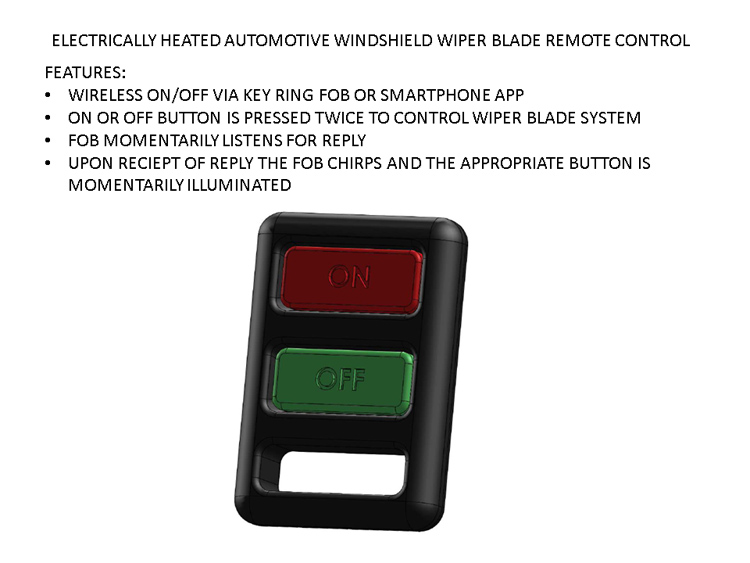

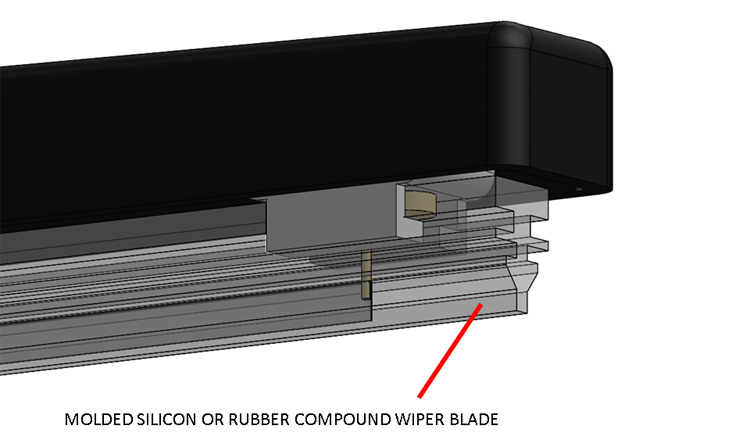

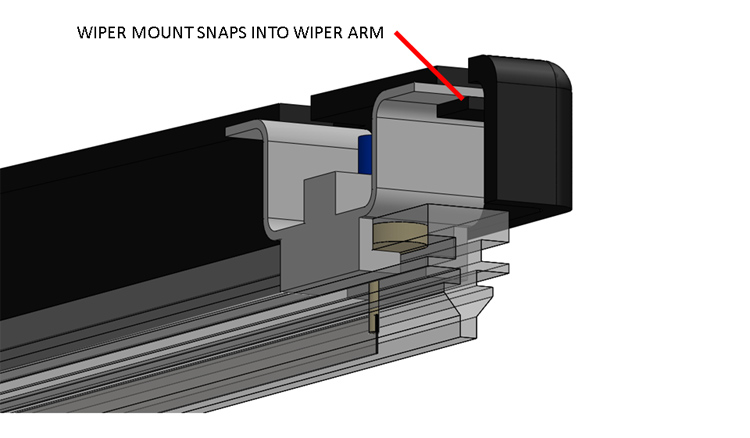

Shelly Blade My friend, Larry, asked me to design and build a prototype for his patented invention, a heated windshield wiper blade. I 3D printed the control box and the simulated windshield. I designed and 3D printed a mold for the silicon wiper blade and cast the blade with an embedded nichrome ribbon heating element and temperature sensor. I designed the electrical system and electronics.

|

|

This video shows the Shelly Blade heated windshield wiper prototype running at a blade temperature of 80 to 90 degrees Fahrenheit. The white tray has a pane of glass with a layer of ice on it.

|

The prototype for the heated windshield wiper blade was 3D printed and controlled by a LEGO Mindstorms system.

|

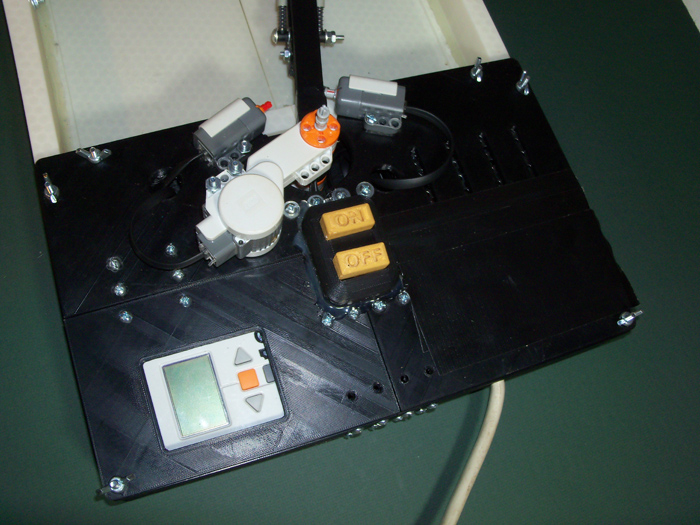

This view shows the LEGO Mindstorms controller, motor, and end of rotation sensors.

|

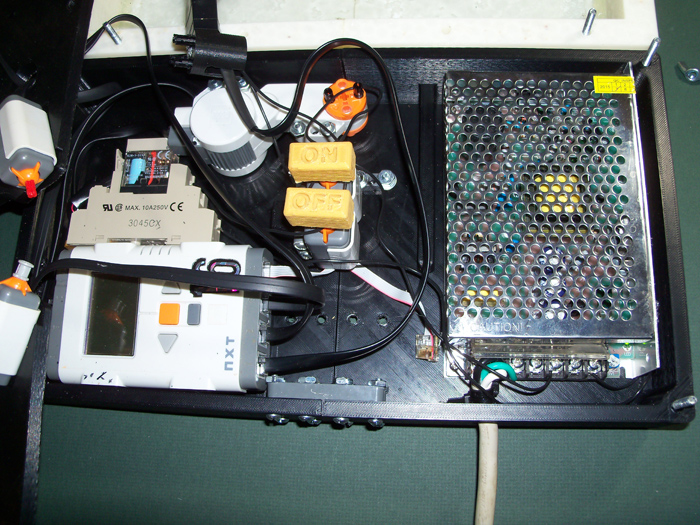

An internal view of the prototype shows a 12 volt DC power supply for the nichrome heating element, a relay which is used to regulate the windshield wiper blade temperature, and the second motor that powers the wiper rotation.

|

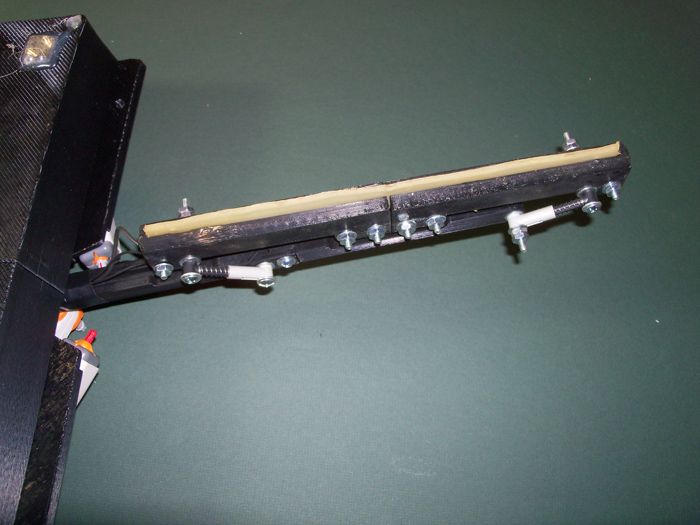

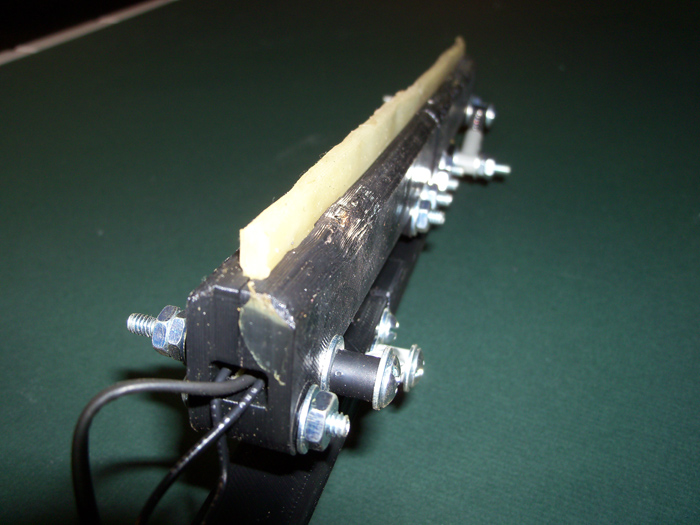

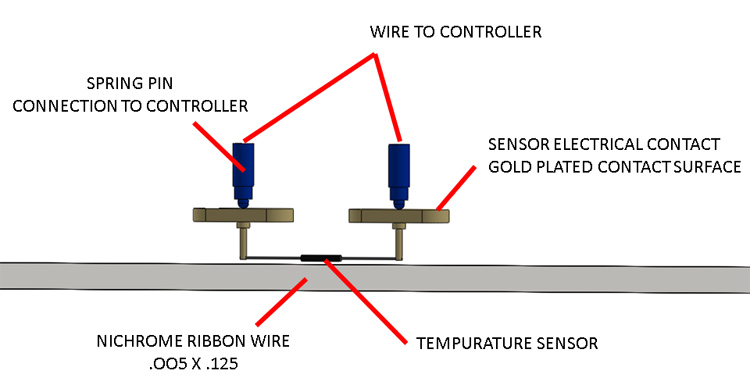

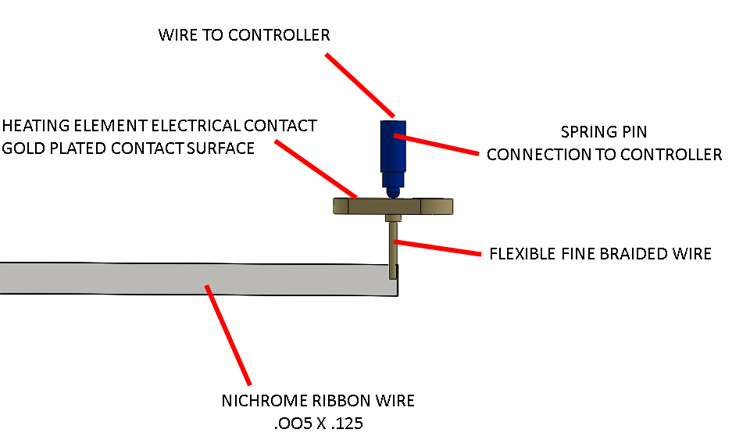

This view shows the wires that supply power to the nichrome ribbon that is molded within the wiper blade and the wire for the temperature probe which is also molded within the wiper blade.

|

A view of the molded silicon wiper blade.

|

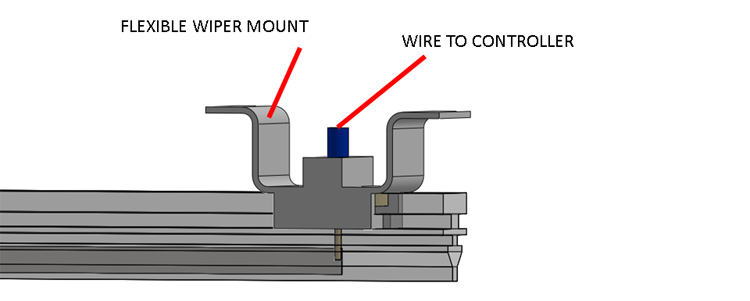

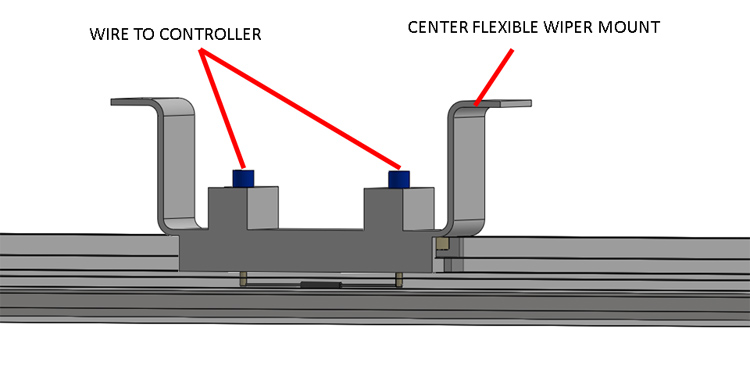

An end view of the wiper assembly.

|

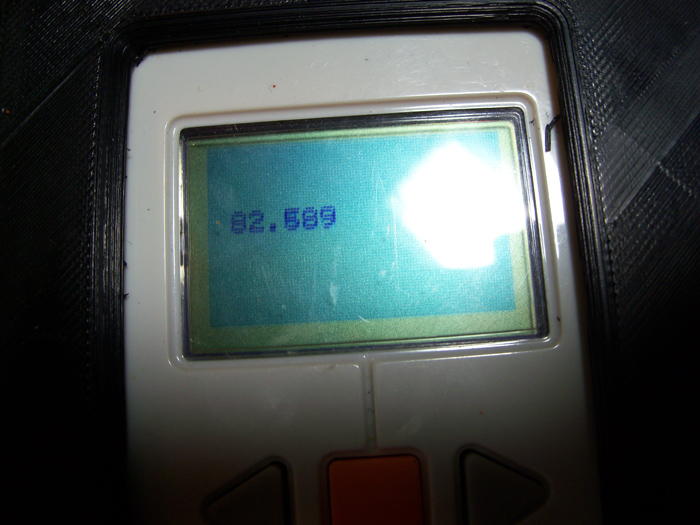

This shows the temperature of the wiper blade in Fahrenheit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|